Author: Mr. Sun Nan and Ms. Zhou Zhenyi

PDA (Pentanediamine) is a novel biobased compound produced through synthetic biology technology using starch or lysine as substrates. In 2004, it was selected by the US Department of Energy as one of the 12 most likely biomass based platform chemicals to replace petroleum based chemicals in the future. Currently, the main downstream product of PDA is bio-based nylon.

Synthetic biology is regarded as the 3rd biotechnology revolution after "DNA double helix structure" and "genome technology". With integrated multiple advantages, including low-carbon, sustainable, and low-cost, synthetic biology can be widely applied in various fields such as pharmaceutical, energy, chemical, agriculture, and environmental protection, etc.

In June 2023, Cathay Biotech and China Merchants Group reached a cooperation agreement, with China Merchants Group investing 6.6 billion yuan to become an indirect shareholder of Cathay Biotech. Furthermore, the two parties have entered into a series of bio based polyamide material procurement agreements to promote its application in China. In addition to Cathay Biotech, companies such as Eppen Biotech and Wanhua Chemical are also vigorously promoting the R & D and industrialization of PDA.

01

Application prospects of PDA

As a biomass based platform compound, PDA can be widely used in fields such as materials, agriculture, and biomedicine. Because of its similar molecular structure to that of petroleum based monomer HDA (hexamethylenediamine), as well as both of them are deriving from biomass, PDA is considered an ideal green substitute for HDA. In the field of materials, PDA can be used as a raw material to polymerize with various dicarboxylic acids to produce a series of bio-based nylon 5X products. Among them, nylon 56 is the most important downstream product, with better physical properties and environmental protection characteristics than that of nylon 66. In addition, PDA’s downstream product PDI (pentamethylene diisocyanate) can be used as the raw material for TPU (thermoplastic polyurethane elastomer) production replacing HDI (hexamethylene diisocyanate). While, in fields of agriculture and biomedicine, PDA can subsitute HDA to be used in fertilizer or used as intermediate for medicine production.

Currently, the main application of PDA is bio-based nylon 5X products. Compared to the traditional PA66, PA5X series products introduce diamine containing odd carbon atoms, which changes the hydrogen bond strength of the molecular structure, thereby affecting the intermolecular interaction force and resulting in changes in the overall performance of the material. Thus, PDA becomes suitable for applying in outdoor sports and wool knitting fields where require unique fabric properties. For example, in the field of wool spinning, PA56 can be blended with wool, cotton, and acrylic fibers to improve the cost-effectiveness of the fabric, while greatly improving its wear resistance, extending its service life, and reducing its operating costs.

PDA is also used for PDI (pentamethylene diisocyanate) production. With a molecular structure similar to HDI, PDI is currently the only biobased isocyanate product. Compared with aliphatic diisocyanate HDI, PDI has the advantage of asymmetric aliphatic structure and better flexibility and transparency, making it an important raw material for biobased PU product, especially biobased TPU. Nanjing University of Technology and Gansu Yinguang Juyin Chemical Industry Co., Ltd., a subsidiary of China North Industries Group, jointly invested in PDI production and its downstream applications. Nanjing University of Technology is responsible for the production of PDA, which will be consumed by Juyin Chemical for PDI production. Currently, Juyin Chemical has completed their PDI pilot test, with the proportion of biobased PDI reaching up to 70%, and the company has also started a small-scale sale in the market.

In agriculture, PDA can effectively improve fruit setting and promote fruit development, thereby increasing the yield of fruits. In medicine, PDA can be used to treat diseases such as dysentery. Quinidine, synthesized from (1,5-pentanediamine, PDA), can be used to treat arrhythmias, and it also has the effects of inducing labor and relieving hypoglycemia. Although these applications are still under exploration and test, their potential for development is enormous.

02

Overtaking! Chinese enterprises take the lead in achieving PDA industrialization

Initially, Chinese enterprises increased their research on the synthesis process and application development of PDA in order to make “breakthrough” in AND (adiponitrile) production technology. In 2021, Cathay Biotech’s 50,000 tons/year of PDA was put into operation, marking China the world's first and currently the only country to achieve commercial production of PDA. At present, overseas companies claiming to have realized PDA production are Toray (Japan), Ajinomoto (Japan), and Daesang (South Korea). Among them, Daesang Corporation is the most active one. It is said that Daesang has achieved PDA production based on its own product lysine in 2023.

Domestic enterprises, represented by Cathay Biotech, have achieved industrial production through breakthroughs in core technologies such as bacteria cultivation in recent years, presenting a landscape of leading enterprises dominating the market. The current representative domestic enterprises of PDA are Cathay Biotech and Eppen Biotech, with Cathay independently developing the technology for PDA production. In June 2021, Cathay’s 50,000 tons/year of bio-based PDA and 100,000 tons/year of bio-based polyamide projects were put into operation. Eppen Biotech uses its self-produced lysine as raw material and relies on the decarboxylation method developed by Chinese Academy of Sciences to produce PDA. Currently, Eppen has already built a production capacity of 10,000 tons/year of bio-based PDA and 20,000 tons/year of bio-based nylon PA56.

The strategies of the two leading companies are slightly different, but both of them are taking full use of their advantages by extending their own industrial chains. Cathay utilizes its synthetic biology and biochemical technology to develop products that cannot be produced by traditional chemical synthesis methods or suffering high production costs. Eppen is a leading enterprise in the lysine industry, with the world's largest lysine market share in 2021. Relying on the cost advantage of upstream raw materials, Eppen started to lay out the production PDA and its downstream bio-based nylon PA56 in 2022.

03

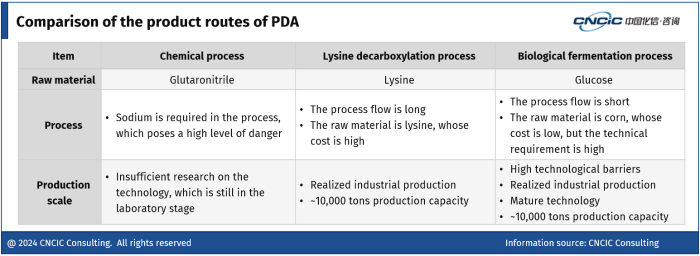

Comparision of different PDA production routes

Comparision of different PDA production routes

04

Insights of CNCIC Consulting

With the development of synthetic biology technology, Chinese companies such as Cathay Biotech and Eppen Biotech have made significant progress in the production and application of PDA. The two companies have not only expanded their production capacity, but also collaborated in R & D with textile enterprises in the downstream market. With the gradual entry of bio based materials into the public eye, it is expected that the supply and demand of PDA will double.

The policy support is the main influencing factor for the development of PDA industry. In 2023, MIIT (the Ministry of Industry and Information Technology), NDRC (the National Development and Reform Commission) and other departments jointly issued the "Three Year Action Plan for Accelerating the Innovation and Development of Non Grain Biobased Materials", which explicitly promoted the development of PDA products in the carbon containing chemicals section of the plan. In the future, with the further refinement of policies, the PDA industry will usher in new opportunities for rapid development.

In perspective of application, PDA is regarded as green product due to its biomass raw material and low carbon footprint in the production process, making it an ideal subsititute of HDA. But with the breakthrough of domestic AND production technology, the cost of PA66 production has significantly decreased, leading to a gradual weakening of the cost advantage of bio-based nylon PA56. In this context, bio-based nylon urgently needs to change its development strategy, and focus on exploring the mid to high end market using the advantages of its green properties, and continue to explore new fields with great application potential.

In summary, PDA, as a biomass based platform chemical product, will usher in new development opportunities with the active support of Chinese government. Especially the application of PDA in polyurethane and agriculture has represented an important direction for the green transformation and upgrading of new materials and agricultural chemicals in the future.